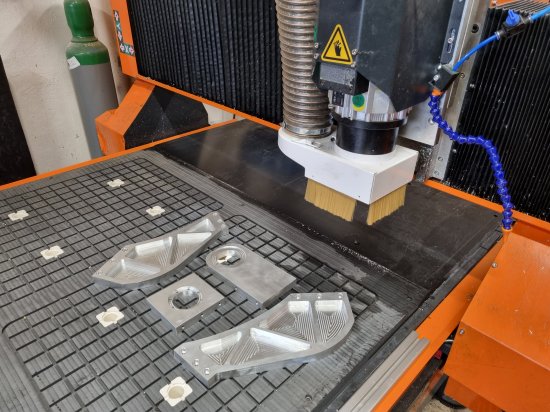

CNC milling machine for aluminum

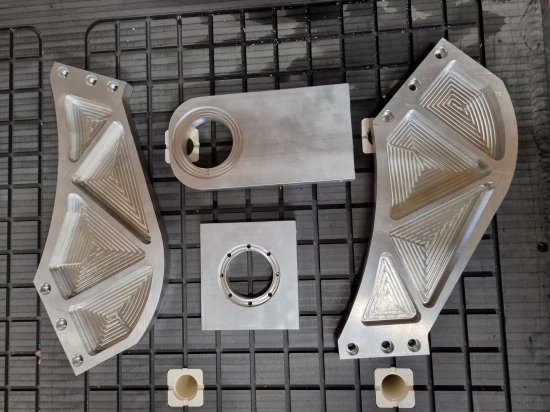

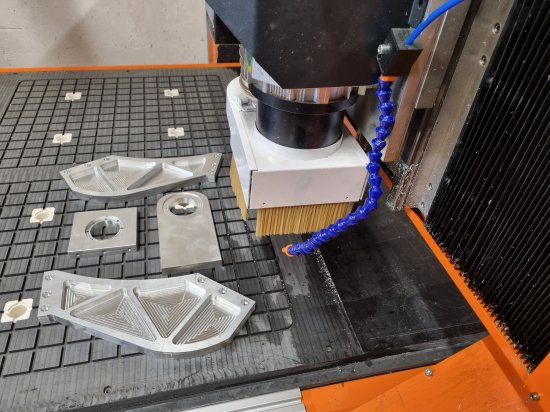

The new model of the CNC portal milling machine for aluminum serves another customer who works with material in the 2x1 m plate format. The Raptor CNC router is equipped with servomotors that can position the tool at a speed of up to 60 m / min. The machined robust construction of the portal milling machine and the linear guide together with the oblique toothed racks ensure an accuracy of + - 0.02 mm. On request, it is possible to supply a CNC router for aluminum also with ball screws in all axes, where the positioning and machining accuracy will be even better. The powerful spindle of a CNC aluminum milling machine and the right tool can leave a completely clean edge in the material. However, it is necessary to lubricate or otherwise cool the cutter.

I am interested in a CNC milling machine for aluminum

Clamping of the material is possible via grooves and clamping jigs or it is possible to use a vacuum table. The choice of the correct clamping depends on the material and form of aluminum machining. The powerful vane pump is equipped with a frequency converter, a pressure sensor and a controller, where the vacuum output is regulated automatically according to current needs. This solution saves electricity consumption and simplifies the work of the aluminum portal milling machine operator. The same applies to the automatic opening / closing of sections at the vacuum table, where the CNC machine knows exactly which parts of the table it is currently machining. But there are far more smart solutions. CNC routers for aluminum already have an automatic tool change with any number of positions in the magazine. The collets and cones used can also be adapted to your wishes, but we most often use BT or HSK with ER25 or ER32.

The basic price of a CNC milling machine includes:

- The size of the workspace according to your specifications

- Robust machined construction of the CNC router, including machining of important parts

- Powerful spindle (min. 6kW) with sufficient torque

- Automatic tool change and any number of positions

- Suction of chips at the working tool, including the basket

- Vacuum table with vacuum pump with power regulation, automatic table sections

- Tool probe including laser cross

- Safety barriers including STOP button

- Freestanding control panel with electronics and software

In addition to the above, you will receive all accompanying services for the purchase of a CNC portal milling machine for aluminum, including, of course, transporting the router to your production, installation of the entire equipment, including tests, operator training on the supplied control system, telephone and online support and a warranty period of at least 2 years. . As a Czech machine manufacturer, we have the opportunity to tailor most parameters to your needs. We focus on an individual approach to the customer and we are able to manufacture a CNC machine completely from scratch and to order. If you are looking for a suitable design for your production, send us an inquiry. We will be happy to work out a technical solution for you, including a price offer, and we will be your partner in machining aluminum and other materials. We are Raptor Technologies.