Fiber lasers Raptor

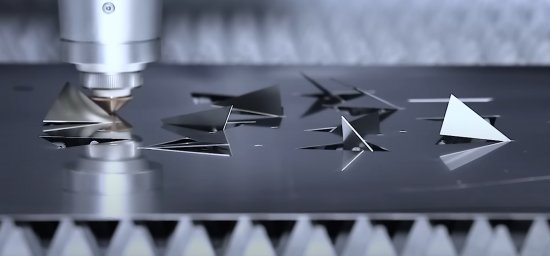

Modern fiber lasers are equipped with a source that generates the beam. This is then directed with the help of a laser head into the cut material. Nowadays, fiber laser power is in the order of kW or tens of kW. In our offer, we have many designs of fiber laser cutting machines with rich basic equipment. We focus on fiber lasers for metal materials in the form of sheets or tubes and profiles. We can also make combined laser machines.

Raptor fiber lasers are made to order, when we adapt the design of the laser, the size of the working surface or the equipment to the customer's wishes. We only use quality components verified by long-term use. Quality comes first, however, at an affordable price. Write to us what you think about the given fiber laser and we will be happy to prepare an individual offer for you.

Fiber lasers are a special type of laser in which the active source that generates the light beam is placed inside an optical fiber. Compared to classical solid-state lasers, which have an active medium in the form of a solid crystal or gas, fiber lasers have an active center formed by a fiber made of optical fibers with high transmission quality.

Basic components

- Laser source with power in kW

- Process head for cutting materials

- The fiber through which the beam is guided

- Control system and drives in CNC design

- Flue gas extractor during the burning process

- Voltage stabilizer

Fiber lasers have several advantages

High efficiency: Fiber lasers achieve high levels of efficiency in converting electrical energy into laser light.

Quality beam: They produce a quality laser beam with high collimation and low divergence, which is useful for many applications.

Compactness: They are much smaller and lighter than conventional solid-state lasers, which makes it easier to integrate them into various devices.

Durability: Fiber lasers are less susceptible to external influences such as vibration or shock due to their

design.

Fiber lasers have a wide range of applications, including industrial marking, cutting and welding of materials, medical imaging and medical procedures, communication networks and many other areas where high quality, precision and reliability of laser radiation is required.

The principle of operation of the fiber laser is based on the amplification of light radiation inside the optical fiber. For a better understanding of this principle, it is important to familiarize yourself with terms such as "stimulated emission" and "resonance".

Fiber laser operation

- Doping the active fiber: The first step is to make an optical fiber with a core (active fiber) doped with certain elements. Doping means adding small amounts of other elements to the fiber core, creating higher energy states capable of performing stimulated emission.

- Energy extraction: Energy is required to amplify the light in the active filament. This is achieved by an energy source, such as an optical or electrical pump, which supplies energy to the active filament. This causes the atoms or molecules in the doped fiber to be excited to higher energy states.

- Stimulated emission: Once the atoms or molecules in the active fiber are in their excited states, a photon hits the atom or molecule in a higher energy state. This causes the atom or molecule to go to a lower energy state and emit a photon. The resulting photon is almost identical to the original photon that acted as a stimulating factor, causing the light radiation to begin to amplify.

- Resonance: The fiber has mirrors at both ends that act as an optical resonator. These mirrors allow the light rays to pass through the active fiber multiple times. This increases the number of stimulated emissions, leading to an increase in the intensity of the laser light.

This is how the process of amplifying the light radiation in the active fiber takes place until it reaches sufficient amplification and creates a laser beam. This beam can have different properties, such as wavelength and intensity, which are determined by the particular doping and construction of the fiber laser.

How much does a fiber laser cutting machine cost?

The cost of fiber lasers varies depending on various factors such as power, wavelength, quality, manufacturer and supplier. Fiber lasers are available in various price ranges and their price starts at 40,000 Euro excluding VAT up to tens of millions of crowns in the case of cutting lasers. Marking lasers are significantly cheaper.

Smaller fiber lasers with lower power and simpler designs that are used for smaller industrial applications or research purposes may be more affordable. On the other hand, advanced fiber lasers with high power, precision and specialized functions that are intended for more demanding industrial processes can have a higher price.

The prices of fiber laser cutting machines also depend on the use and areas in which they are applied. For example, fiber lasers used for laser marking or engraving may be more affordable than those used for industrial cutting or welding.

It is important to note that technology prices may change and market developments may affect the availability and cost of fiber lasers. Therefore, it is always a good idea to compare offers from different manufacturers and suppliers and consider which features and parameters are most relevant for a specific application.