Development of a new CNC lathe

Dear customers,

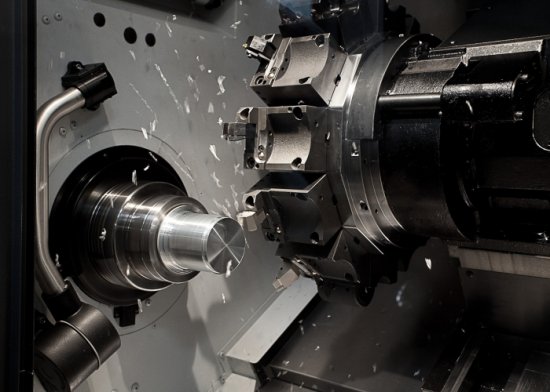

some time ago we accepted a big challenge and started to develop a CNC lathe of our own production. The task was to create a competitive machine with low acquisition costs. After gradually identifying the problems and their subsequent elimination, we managed to develop a turning center with an inclined bed. The inclined bed has the advantage that the chips fall directly into the designated waste container, so they are not caught anywhere during turning. We cool the tool with emulsion liquid and we are able to recycle and continuously use this liquid. The chips from the lathe are taken by an automatic waste conveyor into a designated container next to the machine. We use a hydraulic chuck and a hydraulic tailstock on a CNC lathe for easy clamping of the workpiece. We control the machine from FANUC, but there is also an alternative from Siemens or Mitsubishi Electric. The use of modern technical procedures and suitable composites and alloys allowed us to achieve an accuracy of + -0.008 mm. We only use servomotors for positioning in order to minimize the travel times of the turning tool. On request, we can supply a lathe with automatic tool change with a different number of slots in the magazine. If you are looking for a CNC lathe for your production, do not hesitate to contact us and we will be happy to prepare a non-binding offer for you.

Raptor Technologies - Development of CNC lathe